Tempering Air Fans

Centrifugal Blower Applications for Tempering Air

Tempering is a process that increases the toughness of materials such as steel, aluminum, and glass. In this process, the material is heated above its upper critical temperature or annealing point. It is then rapidly cooled via immersion or forced air draft in a process called quenching. A tempering air fan does the job of quenching in this case. A tempering air fan might also refer to one that rapidly cools hot air coming out of the combustion chamber of an industrial boiler.

Situated downstream from the material tempering process or boiler, the tempering air fan blows clean, fresh air into the gas stream to cool down the air or material quickly. Your tempering air fan environment and airflow will determine your process blower specifications.

Primary Industries for Tempering Air Fans

Many industries use tempered glass, including automotive, building materials, and furniture for safety so that it does not shatter even if broken. Similarly, industries that use tempered steel span across industries such as automotive, aerospace, agriculture, energy & oil, hardware, and even industrial fans. Finally, virtually all industries that use boilers or calciners might also use tempered air fans. It’s very common in power plants and heavy-duty industrial manufacturing. All of these may require tempering air.

Air Tempering Fan Selection & Specification

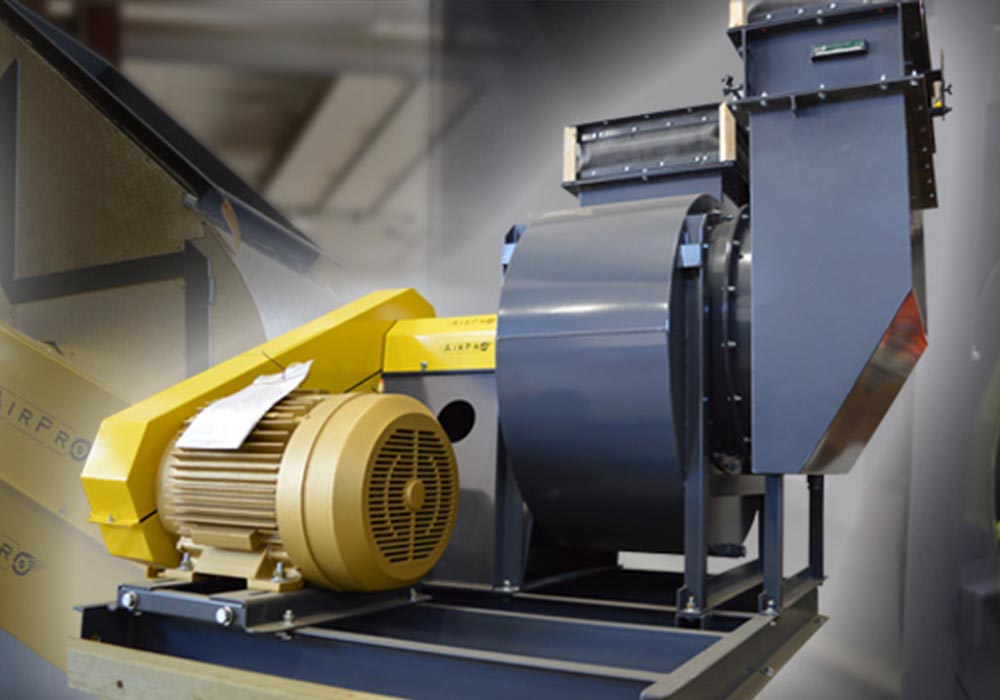

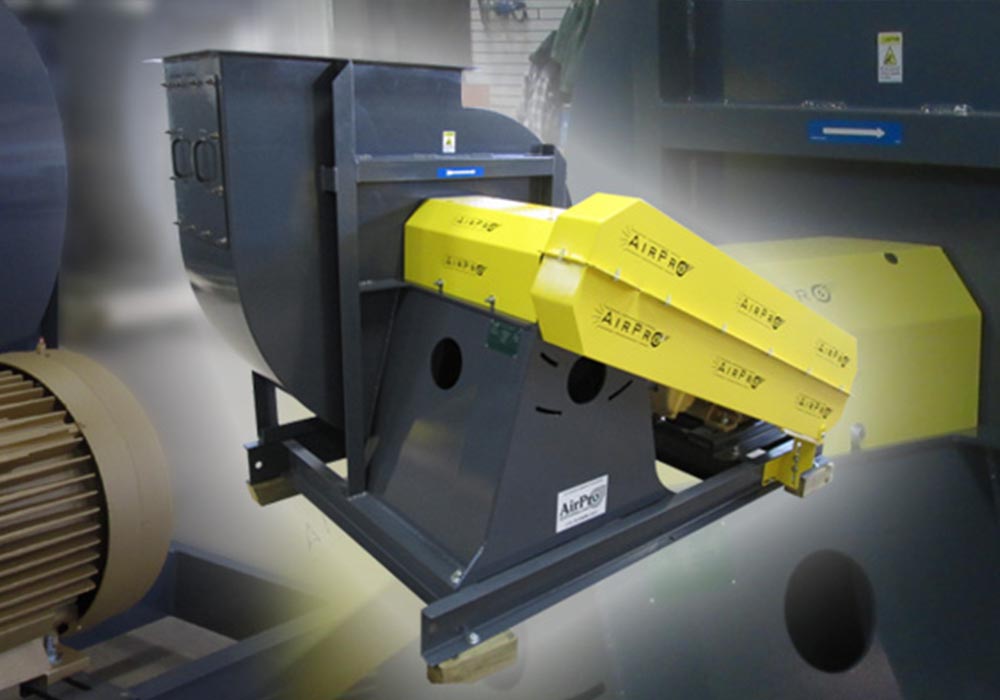

The industrial forced draft fans (FD Fans) used in tempering typically require high volume and high horsepower. Efficiency is always a factor as well, so we often bring in a backward curved model. In fact, in glass tempering, a series of two fans can help supply the necessary pressure and flow without maxing out the fan performance curve. However, there are many options depending on your specific performance requirements.

Fan Designs Used in Tempering Applications

- Backward Curved (BCHS)

- Backward Inclined (BIHS)

- Industrial Exhauster Air Handling (IEAH)

Fan Arrangements

Fan Arrangements indicate how the motors mount to and drive the fan. For a tempering air fan, we typically use a direct drive arrangement, usually, Arrangement 4 or Arrangement 8, unless the blower is very large, in which case we might specify an Arrangement 7:

Arrangement 4 – Direct Drive with an overhung impeller. A low-cost arrangement, the fan wheel mounts directly on the motor shaft.

Arrangement 4V / Top Mount – Direct Drive with an overhung impeller. The wheel also mounts directly on the motor shaft, but in a vertical position.

Arrangement 7 – Direct Drive with a center-hung impeller. The motor is directly coupled to the fan shaft with a bearing on either side of the fan wheel. Involves a bearing on either side of the fan wheel and is supported by the fan housing.

Arrangement 8 – Direct Drive with an overhung impeller. The fan shaft is directly coupled to the motor shaft with a flexible coupling.

Accessories & Design

Installed on the back end of the glass oven, calciner, metal tempering, or boiler system, these fans provide supply air for the tempering process. When it comes to design and accessories, it’s all about protecting and optimizing operations, maintenance, and life of the fan and bearings.

In tempering air applications, we often recommend:

- Double-width housing for higher airflow capacity

- Shaft Grounding System to minimize shaft voltage and prevent current damage

- Flex Connectors to accommodate shifting during rapid temperature change

- Spring Vibration Isolators to protect the fan from excessive vibration

- Inlet Silencer for noise control on the fan inlet

- Inlet Vane Damper, Variable Frequency Drive (VFD), Outlet Damper, or a combination for volume control

- Inlet Filter or Screen to keep the airstream clean and avoid damaging the dampers

- Inlet Box if space is limited for the ductwork

- Vibration and temperature sensors to monitor bearing and fan health and prevent unplanned outages

- Split Housing for easier maintenance access to the fan wheel and shaft

- Proper installation and maintenance to ensure safe startup and operations

Featured Products

Case Studies

Talk with Our Application Engineers

If you feel overwhelmed by all this information, don’t despair! We have a team of application engineers who are happy to talk with you and select the best fan for your application. You can call 715-365-3267, email [email protected], or send us your information, and one of our engineers will connect with you.

Contact UsAirPro Fan & Blower

Connect With Us

Not finding what you need? Contact us