Spray Dryer Fans

Spray Dryer Fan Applications

A spray dryer (single or multi-stage) uses hot gas to process a slurry or liquid to produce a dry powder. This is especially common in food and pharmaceutical manufacturing. Faster than most of the other dryer options, this process atomizes the liquid or slurry through a spray nozzle and into a hot air or gas stream. It vaporizes the water, exhausts the vapor, and separates the solid elements as granules or powder.

The overall spray dryer application can include anywhere from four to nine centrifugal fans. They serve the functions of supply, exhaust, heating, cooling, and a nozzle fan. The supply fan pulls the filtered air heated by the heating fan into the dryer vertically at high velocity, with airflow components designed to prevent particles from sticking to the fan or the inside of the dryer chamber. Once the material is vaporized and dried, a cyclone separates the dried particles into a collector, and the exhaust fan pulls the vapor into an air filtration system. The spray dryer may also involve a cooling air fan to help regulate the pressure of the drying air and the stability of the product. Your application environment and airflow will determine your spray dryer fan selection and specifications.

Primary Industries for Spray Dryer Applications

The spray dryer is a prominent application in these and other industries:

Food Processing

- Animal feed

- Blood & Plasma

- Egg-Cracking Facilities

- Cereals

- Coffee

- Flavorings

- Milk and Whey Powders

- Pet Food

- Plant Proteins

- Spices

- Starch

- Sugar

- Tea

Pharmaceutical Processing

- Additives

- Antibiotics

- Blood Products

- Drugs

- Enzymes

- Medicinal Ingredients

- Vaccines

- Vitamins

Industrial Processing

- Algae

- Ceramics

- Chemicals

- Detergents

- Fertilizers

- Paint Pigments

- Microalgae

Fan Selection & Specification

Because centrifugal fans are prominent at many points in and around the spray dryer application, virtually any of our fans could be used in one or more ways for supply air, exhaust air, process heating, or process cooling. Select and design your fans based on function, flow, and pressure. Here’s a quick overview of the top fans for each main function:

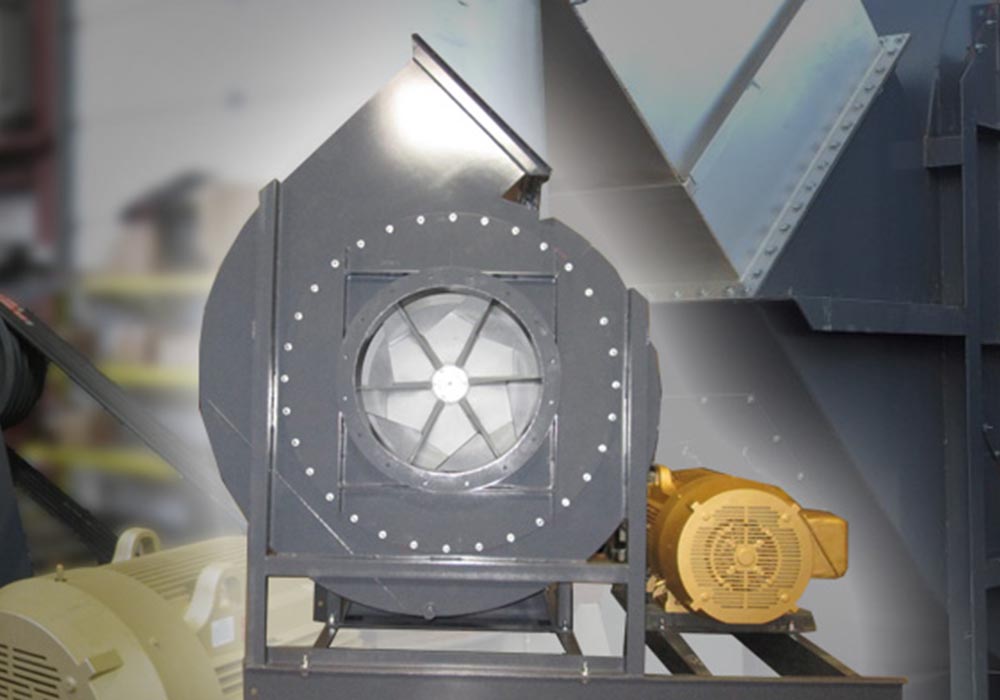

Spray Dryer Supply Fans

- Backward Curved (BCHS)

- Backward Inclined (BIHS)

Spray Dryer Exhaust Fans

- Industrial Exhauster Paddle Wheel (IEPW / IEFB)

- Radial Tipped (RTHS)

Spray Dryer Process Heating Fans

- Plug Fan

- High-Pressure Blowers

- High-Pressure Radial Open (HPRM / HPRL)

Spray Dryer Process Cooling Fans

- Backward Inclined (BIHS)

- Backward Curved (BCHS)

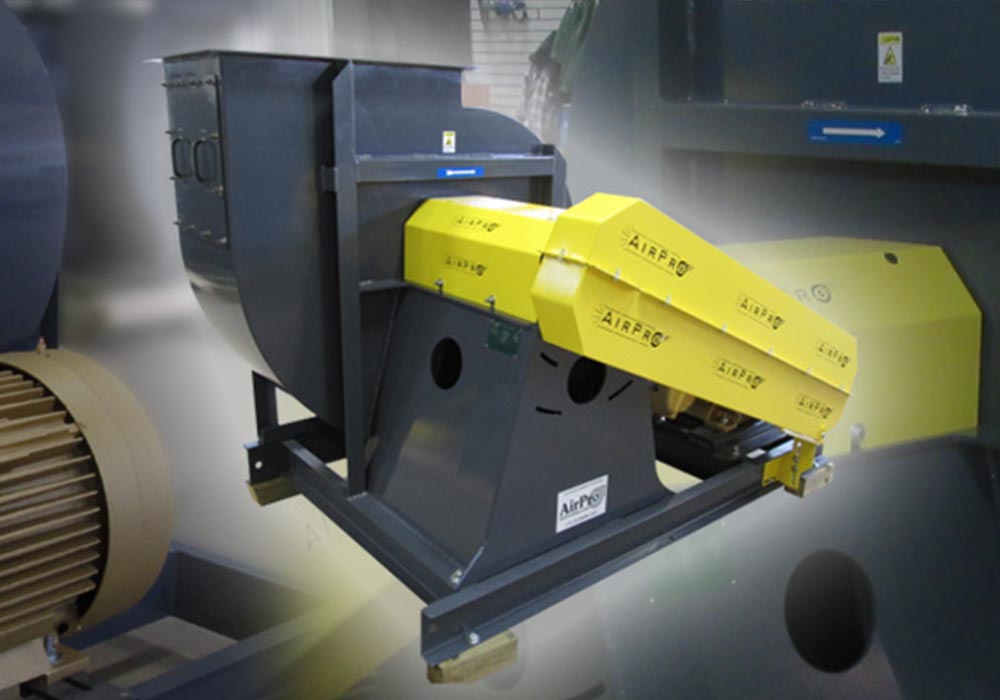

Fan Arrangements

Fan Arrangements indicate how the motors mount to and drive the fans. In this application, the larger supply and exhaust fans will typically run on an Arrangement 8 direct-drive motor with a variable frequency drive (VFD). The smaller cooling and heating fans are often direct-drive Arrangement 4 to minimize the fan footprint.

Arrangement 8 – Direct Drive with an overhung impeller. The fan shaft is directly coupled to the motor shaft with a flexible coupling.

Arrangement 4 – Direct Drive with an overhung impeller. A low-cost arrangement, the fan wheel mounts directly on the motor shaft.

Accessories & Design

When it comes to design and accessories, it’s all about protecting and optimizing operations, maintenance, and life of the fan and bearings. For spray dryer applications, that means designing robust high-quality fans, often with extensive customization to make them food-grade.

Most dairy and food processing applications require stainless steel fans. For some, only the fan airstream parts are stainless, while others dictate that the entire fan be stainless steel, including the motors and safety guards. They also require a smooth, uniform finish and no threads to avoid catching food and water.

These are not merely suggestions for many food and dairy fan applications. The USDA and FDA inspect all food-grade machinery and are meticulous about these requirements, and the fans are required to pass inspection before startup and operation. For spray dryer applications, we often recommend:

Food Grade Considerations for Dairy & Food Processing Industry Fan Applications

- 304 or 316 Stainless Steelmaterials of construction

- Glass Bead Blasting to SSPC-SP10 (the highest weld rating) or chemical treatment for removal of weld discoloration

- 32RA Polishing of the Welds and stainless steel materials for a uniform 32 micro-inch finish

- A Simple Epoxy finish for non-stainless steel components

- Clean-in-Place (CIP) Nozzles inside the fan housing along with a drain system at the bottom of the housing for cleaning access during use

- Stainless Steel Washdown Duty Motor with a Stainless Steel shaft for those requiring all parts in contact with the product be food grade

- Ferrule (Sanitary) Drain, Cap & Gasket with no threads

- Teflon Fan Seals and Housing Gaskets to provide food-grade sealing capabilities

- Flange, Slip Inlet & Slip Outlet allows a flexible boot to connect the fan to the ductwork

Accessory & Design Considerations

- Dampers or Variable Frequency Drives (VFDs) for additional speed control and operating efficiency

- Inlet Box if space is limited for the ductwork

- Inlet Silencer for noise control on the fan inlet

- Vibration Isolators to help the blower stay in balance

- Split Housing for easier maintenance access to the fan wheel and shaft

- Spark Resistance as some gas and dust can be flammable

- Vibration and temperature sensors to monitor bearing and fan health and prevent unplanned outages

- Proper installation and maintenance to ensure safe startup and operations

Featured Products

Case Studies

Talk with Our Application Engineers

If you feel overwhelmed by all this information, don’t despair! We have a team of application engineers who are happy to talk with you and select the best fan for your application. You can call 715-365-3267, email [email protected], or send us your information, and one of our engineers will connect with you.

Contact UsAirPro Fan & Blower

Connect With Us

Not finding what you need? Contact us