Custom Industrial Fans & Blowers

AirPro // Products

Precision-Built Fans Tailored to Your Exact Needs

When standard models can’t meet your airflow, temperature, pressure, or space requirements, a custom-engineered fan provides the right performance and reliability. AirPro designs and builds custom centrifugal fans matched to your exact operating conditions.

Our engineers evaluate your application and recommend a configuration built on proven AirPro design principles; optimized for durability, efficiency, and long-term value. You get the same heavy-duty construction as our standard product lines, enhanced with modifications that ensure the perfect fit for your process.

When a Custom Fan or Blower is the Right Choice

Not every application fits within the limits of a standard industrial fan. When your process demands specific performance characteristics, unique configurations, or operation in harsh environments, a custom-engineered solution ensures you get the exact airflow, reliability, and efficiency your system requires. AirPro’s custom fans are built on proven engineering principles and tailored to solve the challenges that off-the-shelf products can’t address.

Customizable industrial fans are ideal when your process requires:

- Non-standard performance requirements (higher static pressure, unusual volume, or specific operating curves)

- Extreme operating environments including high temperature, corrosive gas streams, abrasive particulates, or moisture

- Unique space constraints or orientations (offset inlets, custom bases, or specialty arrangement configurations)

- Integration into specialized equipment such as ovens, kilns, dryers, mixers, combustion systems, or material handling systems

- Tighter efficiency or energy requirements than standard fan designs can provide

- A match to an existing fan that is no longer serviced by its original manufacturer

Types of Fan & Blower Customizations We Offer

Fan Design Modifications

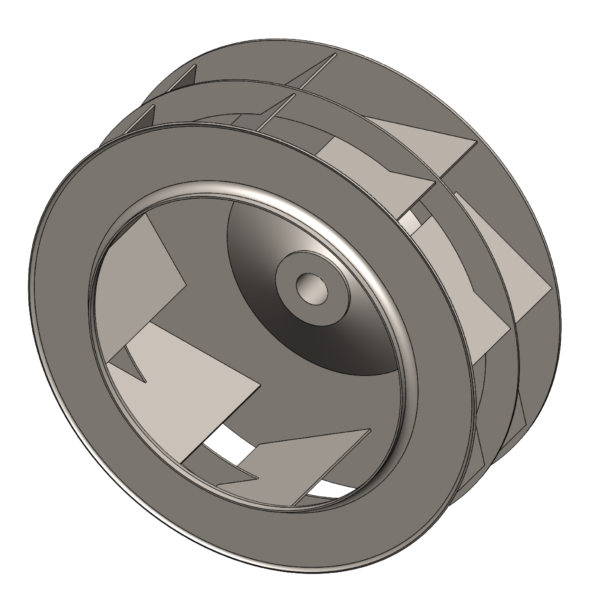

- Wheel design modifications (forward curved, backward inclined, radial, material handling, etc.)

- Custom inlet and outlet sizes

- Performance curve optimization

- Housing geometry modifications

Material & Construction Options

- Carbon steel, stainless steel, Inconel, Hastelloy, and other high-temp or corrosive-resistant alloys

- Specialty coatings and linings

- Food-grade or sanitary construction

- Heavy-gauge construction with high wear resistance for abrasive applications

Accessories & Enhancements

- Custom bases and supports

- Bearings and shaft upgrades

- Silencers, dampers, inlet boxes

- Vibration and temperature monitoring and instrumentation

- Clean-in-place features

- Specialty couplings and drive arrangements

Not seeing a fan customization option you need? Talk with an engineering expert

Why AirPro

Reliable Customizable Fan Solutions Backed by Superior Service

As a 100% employee-owned company, your organization can have absolute confidence when working with AirPro. Over the years, we have built strong customer relationships due to the unmatched quality of product and service that we have to offer. When working with us, you will quickly realize that our response times and customer-driven innovation abilities are simply unparalleled in our industry.

Benefits of a Custom AirPro Fan or Blower:

- Optimized performance for unique or demanding applications

- Longer lifecycle and higher reliability due to tailored materials and construction

- Higher efficiency when standard products don’t meet performance needs

- Integration-friendly designs that drop into your existing system or OEM equipment

- Backed by AirPro’s engineering expertise and proven heavy-duty construction standards and industry-leading 3-year warranty.

How We Engineer Custom Fans

Starting the Custom Fan Conversation

Selecting or designing the right fan begins with a clear understanding of your process requirements. Whether you’re an application engineer ready to dive into technical details or a non-engineer who needs guidance, our team meets you where you are. We speak your language—whether that’s performance curves and air density calculations or straightforward, plain-English explanations.

To prepare for an initial discussion, it’s helpful to gather four key pieces of information:

- Volumetric flow rate

- Fan static pressure

- Inlet air density

- Intended fan duty

If you don’t have this information yet, no problem—our engineers will help you define it. Get In Touch

You can also explore our online fan selection tool, which provides design details, drawings, pricing, and our live chat support with our engineering team during business hours.

Our Custom Fan Engineering Process

- Application Review & System Analysis

We evaluate your airflow, pressure, space, temperature, and environmental requirements. - Engineering & Performance Modeling

Our engineering team develops a design tailored to your performance curve and operational needs. - Material Selection & Design Confirmations

We recommend materials, coatings, accessories, and structural improvements based on your application. - Precision Manufacturing

Fans are built to industrial-duty standards in our USA-based manufacturing facility. - Testing, Balancing, & Quality Checks

Every custom fan undergoes vibration analysis and performance validation before shipment.

Connect with a Custom Fan Engineering Expert

Our application engineers are ready to help you define and design the right custom industrial fan for your process. Whether you’re modifying an existing setup or building a new system, we’ll ensure you get a solution engineered to your exact specifications, performance needs, and timeline. Call, email, or submit your info to get started and our team will respond quickly.