Industrial Selective Catalytic Reduction (SCR) Fans

Engineered airflow solutions for emissions control, compliance, and long-term reliability.

AirPro // Applications

Selective Catalytic Reduction (SCR) Fan & Blower Applications

Selective catalytic reduction (SCR) systems are essential for meeting today’s strict emissions standards in power generation and industrial operations. From boilers and furnaces to heaters and turbines, these systems rely on dependable airflow to keep processes running efficiently while reducing harmful NOₓ emissions before exhaust is released.

AirPro designs and builds centrifugal fans and blowers specifically for the demanding conditions found in SCR applications. Our solutions are engineered for high temperatures, corrosive gas streams, and continuous operation—helping facilities maintain compliance, protect uptime, and avoid costly shutdowns. Whether supporting induced draft, forced draft, or dilution gas functions, AirPro fans deliver the reliability and performance critical to long-term SCR system success.

Primary Industries for Selective Catalytic Reduction Systems

SCR systems are widely used in industries where combustion processes generate nitrogen oxides (NOₓ), volatile organic compounds (VOCs), and hazardous air pollutants (HAPs). These systems are critical for reducing emissions, meeting environmental regulations, and maintaining safe, compliant operations. Industries that commonly rely on SCR systems include:

Power Generation & Steam Production Applications

- Coal-fired power plants

- Natural gas power plants

- Combined-cycle power generation facilities

- Utility and industrial steam boilers

- Cogeneration and CHP systems

Industrial Combustion & Process Applications

- Process and package boilers

- Fired heaters and thermal oxidizers

- Industrial furnaces and high-temperature process heaters

- Chemical and petrochemical processing

- Refining and fuel processing operations

- Pulp and paper manufacturing

- Cement, lime, and building materials production

- Steel, metals, and foundry operations

- Waste-to-energy and incineration facilities

SCR System Fan Selection & Specification

Strict EPA emissions regulations make SCR systems a critical part of many industrial and power-generation operations, and the fan is central to system performance and reliability.

In SCR applications, fans are installed downstream of the combustion process and must move exhaust gases at extremely high temperatures, often exceeding 1,000°F. These harsh conditions create significant system resistance and demand fan designs capable of delivering high pressure while maintaining long-term durability. To meet these requirements, SCR fans are engineered for high tip speeds, robust construction, and stable operation under continuous thermal stress.

While shrouded or open radial wheels are a common choice for low volume, moderate-to-high pressure SCR systems, AirPro evaluates each application individually. Operating temperature, pressure requirements, particulate loading, and system layout all influence the optimal fan design and configuration.

Industrial Fan Designs Commonly Used for Selective Catalytic Reduction Systems

- Pressure Blowers

(P##A/B/C/D) - Extreme Pressure Blowers

(XP#O/S) - Backward Curved

(BCHS, BCES, BCMS, BCLS, BCNS)

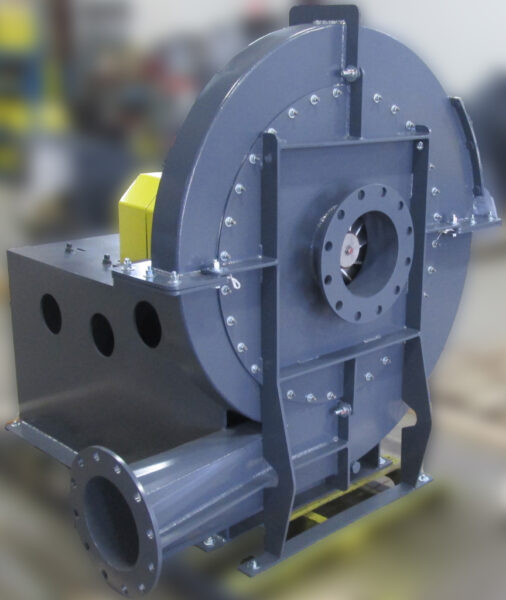

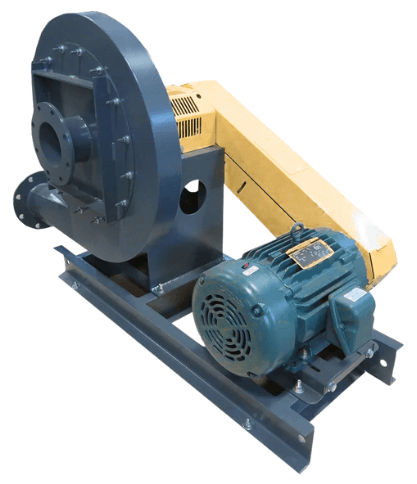

FEATURED FAN

Custom SCR Blowers for Petroleum & Chemical Manufacturing

AirPro engineered and manufactured a set of custom high-pressure SCR blowers—one primary unit with an identical redundant backup—for a mission-critical selective catalytic reduction (SCR) system in a petroleum and chemical manufacturing facility. Redundant airflow is essential in SCR applications, as uninterrupted operation is required to maintain emissions compliance.

These blowers handle NOₓ-laden flue gas produced by combustion processes, supporting catalytic treatment before exhaust is released. To meet strict U.S. Environmental Protection Agency (EPA) regulations, the system must deliver consistent, reliable airflow under demanding operating conditions.

Designed for high-temperature service, the blowers operate at up to 800°F with a tightly controlled 15-degree minimum/maximum rate of temperature change. Each unit is equipped with severe-duty, premium-efficiency IEEE 841–rated motors to ensure durability and long-term performance in harsh process environments.

- Product Type: BCHX (backward curved)

- Description: Class 5, Arr. 8 (direct-coupled drive), 150ºF max temp design

- Performance: 22,000 CFM @ 26” wg static pressure

- Features: Custom-engineered high-pressure design; redundant primary and backup blower configuration; backward-curved wheel for efficiency and stability; severe-duty IEEE 841–rated motors; designed for tight thermal ramp rates; built for continuous operation in petroleum and chemical processing environments

SCR Fan Arrangements, Accessories, & Design

Industrial selective catalytic reduction fan arrangements commonly used:

Fan arrangements indicate how the motors mount to and drive the fans. The Selective Catalytic Reduction System can use both direct drive and belt drive options, but the most common is direct-drive Arrangement 8. These are the arrangement options:

Arrangement 1 – Belt Drive with an overhung impeller. The fan and motor mount separately to a unitary base.

Arrangement 7 – Direct Drive with a center-hung impeller. The motor is directly coupled to the fan shaft with a bearing on either side of the fan wheel. Common in API 560 and 673 applications.

Arrangement 8 – Direct Drive with an overhung impeller. The fan shaft is directly coupled to the motor shaft with a flexible coupling.

Common fan design & accessory considerations for SCR fan applications:

When it comes to design and accessories, it’s all about protecting and optimizing operations, maintenance, and life of the fan and bearings. In industrial selective catalytic reduction systems, we often recommend:

- Housing Insulation – to protect the bearings from the heat radiating off the fan housing

- Shaft Cooler – (aka Heat Slinger) to dissipate heat from the fan or blower shaft

- Increased Internal Clearances – to allow for thermal expansion

- Flex Connectors – to allow the housing and ducting to thermally grow without impacting each other negatively

- Purgeable Shaft Seal – to help prevent hot air from getting to the bearings through the shaft hole opening

- Monoblock Bearings – (instead of separate bearings) to hold tight alignment and keep temperatures down at high speeds

- Stainless Steel Shaft – to provide a lower rate of thermal conductivity than carbon steel, protecting the bearings from the hot gas stream

- Vibration and Temperature Sensors – to monitor bearing and fan health in real time, enabling predictive maintenance and reducing unplanned downtime

- Center-Supported Housing – to keep thermal growth originating at the center of the shaft

Talk with an SCR Fan Application Engineer

Our experienced application engineers are ready to help you find the right fan. Whether you’re replacing an existing unit or designing a new system, we’ll make sure you get a solution that fits your specs, timeline, and budget.

Call, email, or submit your info to get started and our team will respond quickly.