Quality Assurance & Control

Quality control and positive material identification for quality assurance.

AirPro // Features

Quality Assurance and positive material identification are not luxuries or items on a wish list. They are indeed considered essentials here at AirPro.

AirPro

Quality Assurance & Control

We test and rate our product lines in accordance with Air Movement and Control Association (AMCA) standards; We develop and design our products utilizing Solidworks, Driveworks, and PDM to perform Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and ensure standardization and revision control; We weld all of our metals using American Welding Society’s (AWS) control parameters and apply those welds with fabricators trained and qualified to weld by our in-house Certified Weld Inspectors (CWI); We balance products in compliance with International Standards Organization (ISO) standards for rotating machinery; and finally we assure this consistent daily quality through our management system which has been certified as ISO 9001:2015 compliant.

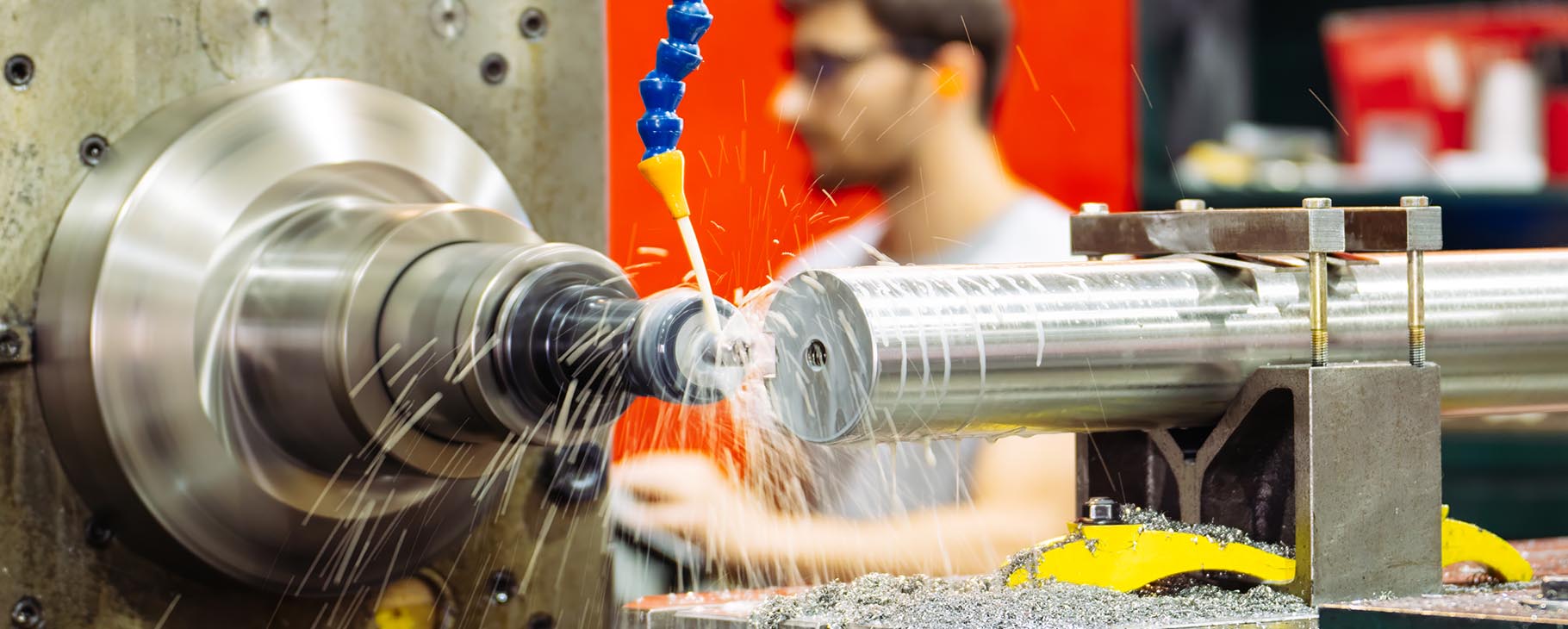

Manufacturing Process For Quality Assurance

The AirPro manufacturing process is one of the major supporting components to the AirPro guarantee of superior quality. Through our process, we:

- Identify and track the materials throughout the manufacturing process to ensure properties are consistent with order requirements for centrifugal fans and blowers.

- Maintain Mill Test Reports (MTRs) for grades above A36. An MTR documents end-to-end positive material identification, traceability and assurance about the quality of the steel used and how it was made.

- Calibrate and maintain tools and equipment according to schedule for precision and accuracy.

- Fabricate all of our metal in accordance with AWS standards and in-house Weld Process Standards (WPS).

- See projects through with in-house project managers assigned to stay with jobs throughout the entire order cycle.

AirPro Quality Assurance & Control

Quality Control Inspections

We conduct inspections to ensure that each AirPro fan not only complies with the customer’s requirements, but that it also maintains AirPro’s high standard of quality control. These inspections take place throughout the manufacturing process, which includes these essential steps:

- Order entry

- Release of design to manufacturing

- Material receiving and preparation

- Material kitting and labeling

- Fabrication and welding

- Paint/coating and surface preparation

- Product final assembly

- Balance and vibration analysis

- Final inspection before shipping

- QC documentation provided to the customer

Special linings: Generally applied to the fan interior for added protection from corrosive and abrasive materials.

- Rubber: A tough elastic polymeric material that coats the inside of containers to prevent corrosion.

- Ceramic tile: Wear-resistant, fire-resistant, anti-corrosion, non-oxidizing, ceramic linings effectively prolong the service life of the equipment.

- Teflon: Teflon industrial liners protect equipment in harsh, high-heat applications. Most Teflon coatings for industrial use require a primer coat.

Other custom coatings are available – just ask an application engineer!

Why Quality Assurance is so Important to Us

As a 100% Employee-Owned company, AirPro Fan & Blower lives out its mission and its promises. When we say we guarantee superior quality, that means that each individual employee-owner absolutely GUARANTEES it. We have thoughtfully built accountability into our process and it is part of everything we do for our customers.