Industrial Thermal Oxidizer & RTO Fans

High-efficiency fans built to handle extreme heat, corrosive gases, and continuous-duty performance.

AirPro // Applications

Centrifugal Fans & Blowers for Thermal & Regenerative Thermal Oxidizers

Thermal oxidizers (TOs) and regenerative thermal oxidizers (RTOs) use high-temperature combustion to break down hazardous gases—such as volatile organic compounds (VOCs) and hazardous air pollutants (HAPs)—into harmless byproducts like water vapor and carbon dioxide. These systems are essential for meeting EPA emission standards and maintaining safe, compliant operations.

Centrifugal fans are the driving force that move process air through the oxidizer’s chambers, maintaining the airflow and pressure needed for complete combustion. AirPro’s engineers will work with you to specify the right fan for your airflow, temperature, and system design—whether for a new unit or a retrofit.

Primary Industries for Thermal Oxidizers

Many industrial processes generate hazardous air pollutants (HAPs) or volatile organic compounds (VOCs) as byproducts. Thermal and regenerative thermal oxidizers are essential for meeting air quality regulations and ensuring safe, compliant operations across a wide range of sectors. Industries commonly using thermal oxidizers include:

- Animal feed production

- Automotive manufacturing

- Building materials manufacturing

- Chemical processing

- Chrome plating

- Food & beverage processing

- Metal finishing & fabrication

- Wastewater treatment

- Oil & gas production & refining

- Paint & surface coatings

- Pharmaceuticals

- Printing, packaging & labeling

- Rubber & plastic manufacturing

- Semiconductor & electronics production

Thermal Oxidizer Fan Selection & Specification

Thermal oxidizers are essential for air pollution control—and the process air fan is a mission-critical component within that system. Choosing the right fan technology directly impacts system performance, uptime, and compliance with emission regulations.

Thermal oxidizer applications demand industrial fans that deliver high efficiency, withstand extreme temperatures, and resist corrosive gases. That’s why AirPro’s backward-curved centrifugal fans are among the top-performing choices. These models can achieve up to 85% efficiency, helping to reduce energy costs while maintaining reliable airflow under harsh conditions.

Depending on your system design, we also offer proven alternatives such as Backward Inclined (BIHS) and Radial Tipped (RTHS) fan models.

Every fan we build is engineered for your specific application—balancing efficiency, durability, and performance to keep your oxidizer system running at peak operation.

Fan designs commonly used on thermal oxidizers:

- Backward Curved

(BCHS, BCMS, BCLS) - Backward Inclined

(BIHS, BIMS, BILS, BIHD) - Radial Tipped

(RTHS, RTMS)

FEATURED FAN

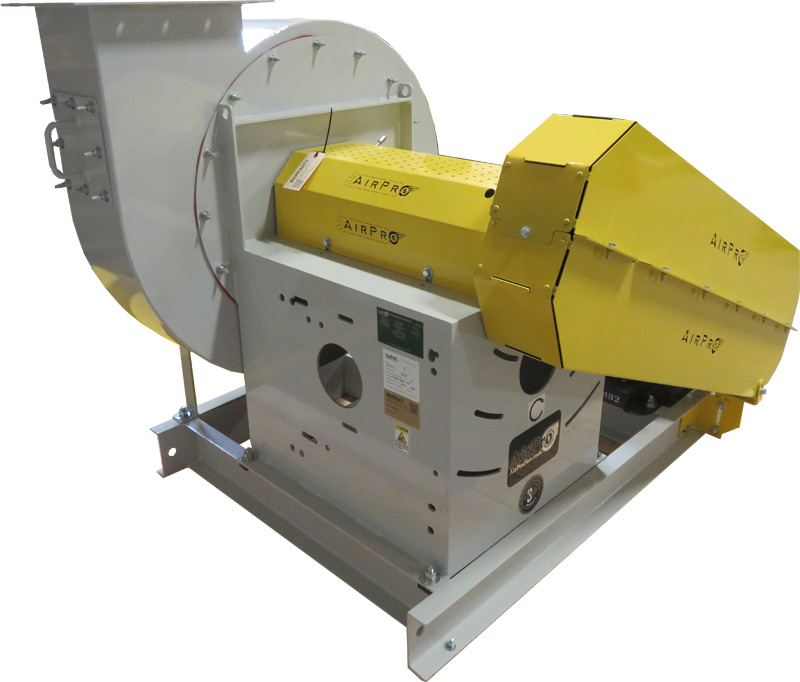

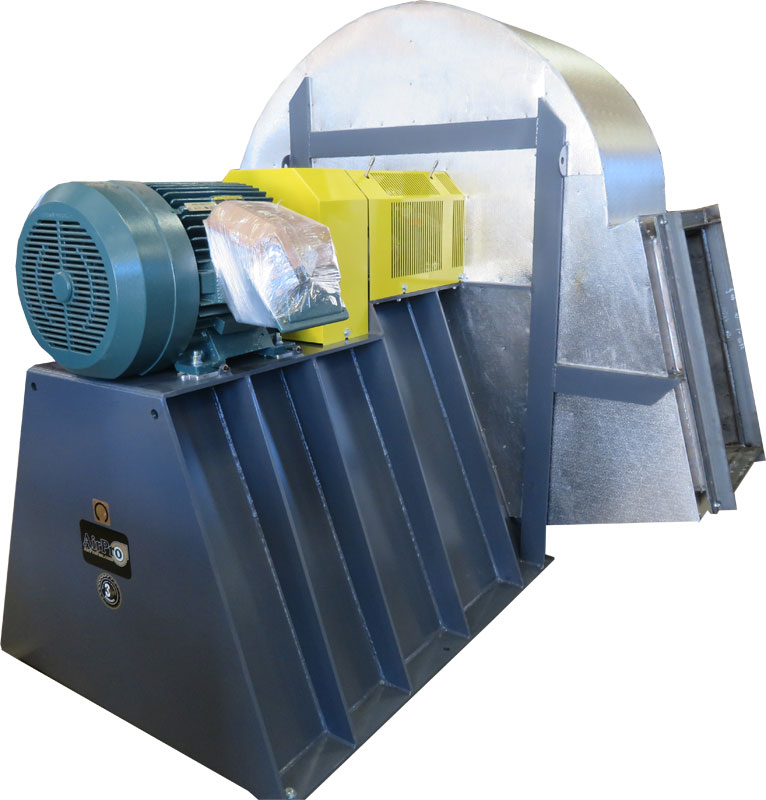

High-Temp Fan for Regenerative Thermal Oxidizer System

For a regenerative thermal oxidizer (RTO) application in a high-heat, VOC-heavy environment, AirPro engineered a custom backward-curved centrifugal fan rated for continuous operation at up to 500°F. To ensure safe and efficient performance, the fan included thermal insulation with aluminum cladding, spark-resistant construction, and vibration sensors on the bearings to monitor and protect against excess vibration.

Additional features included companion flanges, extended lube lines for easy maintenance, and an inlet box for optimized airflow. Built for a pollution control system in a demanding industrial setting, this fan delivered high efficiency and durability while supporting Clean Air Act compliance across industries like chemicals, semiconductors, pharmaceuticals, and coatings.

- Product Type: BCMS (backward curved)

- Description: Class 40, Arr. 8, 500ºF max temp design

- Performance: 24,000 CFM @ 16″ wg static pressure

- Features: Custom-designed; 75 HP motor; direct-coupled drive; thermal insulation; aluminum cladding; vibration sensors; companion flanges, extended lubrication lines; inlet box

Thermal Oxidizer Fan Arrangements, Accessories, & Design

RTO fan arrangements commonly used:

Fan arrangements indicate how the motors mount to and drive the fans. Thermal oxidizers and RTOs most often use an Arrangement 8 coupled direct-driven process fan and an Arrangement 4 direct-driven combustion blower.

Accessories & design considerations for RTO fans and blowers:

In thermal oxidizer systems, fan design and accessories play a critical role in protecting the system, extending equipment life, and ensuring safe, efficient operation. It’s not just about selecting a fan; it’s about engineering a complete solution that supports long-term performance and maintainability.

Most systems also require a combustion air blower to supply air to the burner. Learn More >

Thermal oxidizer features:

- Spark-Resistant Design – helps reduce risk in systems where flammable gases may be present

- Modular Base Design – Pedestals that don’t require concrete or rebar to reduce vibrations due to frequencies at varied operational speeds

- High-Efficiency – Reduces energy consumption and operating costs while supporting sustainable operations

For RTO applications, we often recommend the following fan or blower accessories:

- Variable Frequency Drives (VFDs) – for additional speed control and operating efficiency

- Vibration and Temperature Sensors – to monitor bearing and fan health in real time, enabling predictive maintenance and reducing unplanned downtime

- 304 or 316 Stainless Steel Construction – used when handling corrosive or toxic airstreams to improve durability and system integrity

- Insulated Airstream – on the process fan in a high-temperature situation to keep the outside surface of the fan housing below 140°F to the touch for personnel safety and comfort

- Final Trim Balance – balanced to a maximum of 0.124 in/sec (filter-in) at full speed to minimize vibration and maximize fan and bearing life

- Flex Connectors – to accommodate shifting during rapid temperature change

- Inlet Box – a solution for installations with limited ductwork space on the inlet side

- Split Housing – for easier maintenance access to the fan wheel and shaft

- Vibration Isolators – to help the blower stay in balance

Connect with a Thermal Oxidizer Fan Expert

Our experienced application engineers are ready to help you find the right fan. Whether you’re replacing an existing unit or designing a new system, we’ll make sure you get a solution that fits your specs, timeline, and budget.

Call, email, or submit your info to get started and our team will respond quickly.