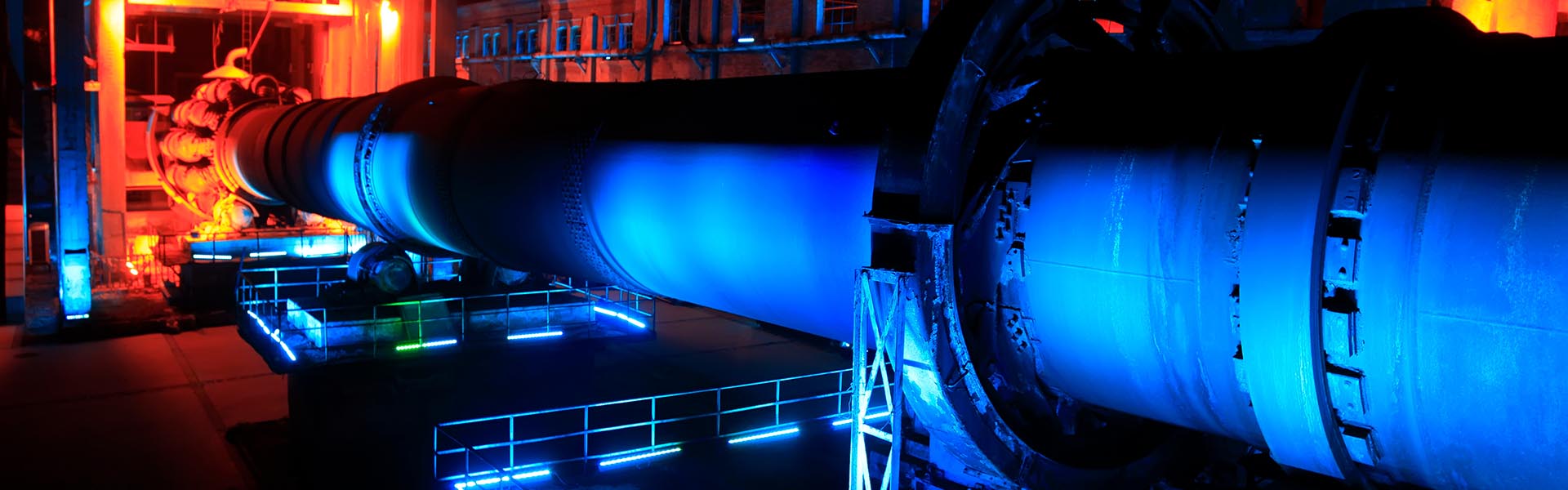

Industrial Fans & Blowers for Calciner Rotary Kilns

Engineered for high-temperature applications, moisture removal, and consistent product quality.

AirPro // Applications

Centrifugal Fans and Blowers for Calciner Rotary Kiln Applications

Industrial calciners, specifically indirect rotary kilns, are essential in processes like moisture removal during the production of materials such as cement, lime, and gypsum. These kilns consist of a rotating drum inside an externally-heated furnace, reaching temperatures up to 3000°F. Maintaining even temperature distribution across the drum is crucial for ensuring consistent product quality.

In these high-heat environments, large supply fans draw clean ambient air into the rotating drum, where it circulates over the material to extract moisture. The resulting product, such as clinker in cement production, exits through the product outlet. Exhaust fans are also used to remove gases and water vapor, which are then processed through pollution control systems like oxidizers or baghouses.

Primary Industries for Calciner Fans & Blowers

Many varied industries use calciners in their processes. The indirect rotary kiln is a prominent application in these and other industries:

- Cement

- Infrastructure

- Building materials

- Lime/limestone

- Gypsum

- Process metallurgy

- Food processing

- Pharmaceuticals

Calciner Fan Technology Selection & Specification

For optimal performance, the fan used to supply clean ambient air into the calciner drum should feature high-efficiency models with backward inclined or backward curved impellers. The fan size and design are determined by the required airflow, with only a few specific models typically selected based on the unique needs of each application.

Typical design types for calciner fans:

Backward Curved

- BCES — High-Efficiency Single-Width

- BCHD — High-Volume Double-Width

- BCHS — High-Volume Single-Width

- BCLS — Low-Volume Single-Width

- BCMS — Medium-Volume Single-Width

- BCNS — Narrow Single-Width

Pressure Blowers

- P##A — Shrouded Radial Aluminum Wheel

- P##B — Open Radial Steel Wheel

- P##C — Shrouded Radial Aluminum Wheel

- P##D — Open Radial Steel Wheel

- P##G — Backward Curved Shrouded Steel Wheel

- XP10 — Narrow Extra Low Flow, Open

- XP20 — Wide Extra Low Flow, Open

- XP1S — Narrow Extra Low Flow, Shrouded

- XP2S — Wide Extra Low Flow, Shrouded

Backward Inclined

- BIHD — High-Volume Double-Width

- BIHS — High-Volume Single-Width

- BILS — Low-Volume Single-Width

- BIMS — Medium-Volume Single-Width

Industrial Exhausters

- IEAH — Industrial Exhaust Air Handler

FEATURED FAN

Calciner Supply Fan for High-Temperature Rotary Kiln Application

AirPro engineered and built a high-performance supply fan for a rotary kiln application. Designed to operate in extreme temperatures up to 475°F, the radial-tipped fan features a v-belt drive and unitary base, ensuring durability and efficient airflow. This fan is critical for the calciner process, where ambient air is pulled in to dry materials entering a rotating drum inside an externally-heated furnace. With high-efficiency performance at low static pressures, the fan is built with extra margin to accommodate the variable speeds required for drying processes.

- Product Type: RTHS (radial tipped)

- Description: Class 4, Arr. 1 (belt drive with unitary base), 475ºF max temp design

- Performance: 64,000 ACFM @ 14” wg static pressure

- Features: Custom-designed; radial tipped fan; v-belt drive; unitary base; high-temp construction; 250 HP motor; heavy-duty performance; extra margin for speed accommodation

Calciner Fan Arrangements, Accessories, & Design

Common fan arrangements for calciner rotary kilns:

Fan arrangements define how the motor connects to and drives the fan. The motor size plays a key role in determining the arrangement. For most calciner fans, an Arrangement 1 belt-drive motor is used for motors up to approximately 250HP. When the motor exceeds 250HP, which is common in larger applications, an Arrangement 8 direct-drive configuration is typically used.

Arrangement 1

Belt drive with an overhung impeller. The fan and motor mount separately to a unitary base.

Arrangement 8

Direct drive with an overhung impeller. The fan shaft is directly coupled to the motor shaft with a flexible coupling.

Common fan design & accessory considerations for calciner rotary kilns:

Design and accessories are crucial for protecting and optimizing the fan’s operation, maintenance, and longevity, particularly when considering the bearings. In rotary kilns, one challenge is accurately calculating the drying process. If the system is too close to its maximum capacity, more speed may still be needed. To mitigate this, we recommend designing with a 15% performance margin to allow for flexibility and ensure optimal performance under varying conditions.

In industrial calciner applications, we often recommend:

- Custom Airstream Alloys – High temp carbon steel alloys or stainless steel alloys are often necessary to meet high temperature requirements

- Flex Connectors – accommodates shifting during rapid temperature change

- Custom Shaft Seal – separate internal hot gas from external ambient conditions

- Inlet Box – a solution for installations with limited ductwork space on the inlet side

- Vibration Isolators – required when foundational mass is insufficient to support fan operation

- Vibration and Temperature Sensors – monitor bearing and fan health and prevent unplanned outages

- Split Housing – for easier maintenance access to the fan wheel and shaft

- Thermal/Sound Insulation Jackets – Reduce external housing temperature and/or radiated noise levels around the fan

Connect with a Calciner Fan & Blower Expert

Our experienced application engineers are ready to help you find the right fan. Whether you’re replacing an existing unit or designing a new system, we’ll make sure you get a solution that fits your specs, timeline, and budget.

Call, email, or submit your info to get started and our team will respond quickly.