Industrial Material Handling Fans & Blowers

Heavy-duty fans built to handle abrasive & bulk materials.

AirPro // Applications

Fans & Blowers for Industrial Material Handling Applications

In industrial material handling, fans play a vital role in moving everything from fine particles like dust and grain to heavy, abrasive materials like metal scrap and wood chips.

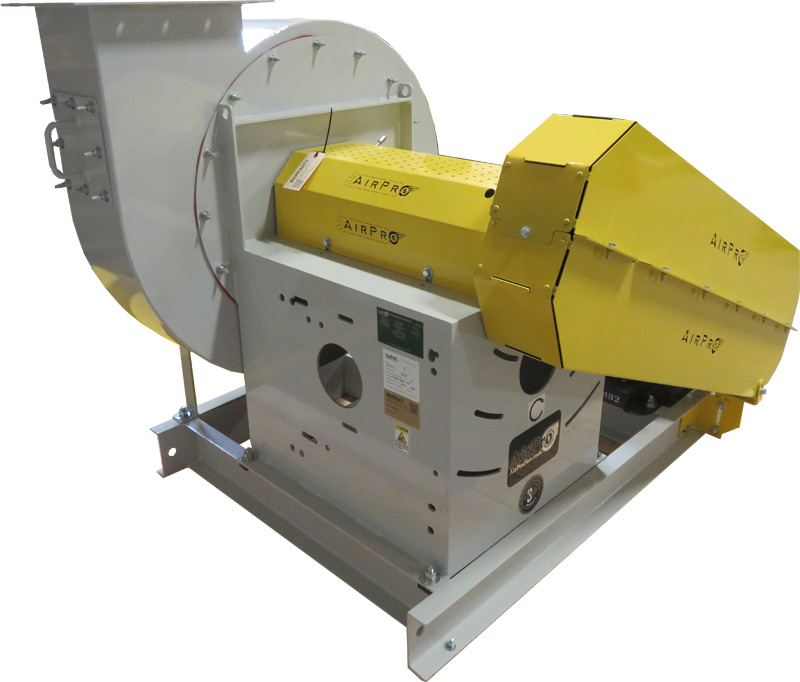

AirPro’s heavy-duty centrifugal radial fans—available in both Open and Shrouded designs—are built for durability and performance, providing reliable air movement and pneumatic conveying across a wide range of manufacturing environments.

Primary Industries for Material Handling Fans

The industry of operation is a primary indicator of the application environment and fan function. Almost all process industries involve some sort of material handling fan, including but not limited to:

- Automotive OEM

- Building materials

- Consumer goods

- Food & grain

- Paper & pulp

- Pharmaceuticals

- Plastics recycling operations

- Trim

- Woodworking

Material Handling Fan Technology Selection & Specification

The material being processed requires careful consideration for the design and specification of the industrial material handling fan.

Choosing the most effective material handling fan technology for your application is critical. The materials that move through the pneumatic equipment are often abrasive, and sometimes combustible or explosive (for example, flour, wood dust, or paper). In many applications, the materials can also get trapped and clog the system without the right construction.

High-pressure blowers may be used to pneumatically convey product/material through the manufacturing process, including venturi eductors. Radial/paddlewheel design fans convey material to/through dust collection systems and from collection system discharge to bins, silos, containers, etc. There are also designs that specifically address Trim Handling as a specific type of material handling.

Material handling fan performance:

- Volume: up to 500,000 cfm

- Pressure: up to 35”wg

- Temperature: up to 1800°F

- Static Efficiency: up to 81%

- Drive: Belt & Direct

Fan designs commonly used for material handling applications:

Industrial Exhauster Paddle Wheel

(IEPW)

Its open radial blades resist clogging and easily handle abrasive, fibrous, or bulky materials, making it ideal for tough material handling jobs.

Industrial Exhaust Flat Backplate

(IEFB)

Utilizes the same design as the IEPW, but also includes a backplate. The IEFB is provided with arrangement 4, direct-drive fans in order to protect the motor from material entering the fan airstream.

Industrial Exhauster Trim Handling

(IETW)

Starts with radial blades and includes a backplate. Gussets are added for additional support and strength. This design is used to convey and exhaust edge trim, such as paper, cardboard, and various metals.

Industrial Exhauster Trim Xtra-Duty

(IETX)

An extra heavy-duty version of the IETW model, also used for trim removal.

Industrial Exhauster Radial Shrouded

(IERS)

Shrouded radial fans include radial blades with a shrouded wheel to increase efficiency. Extra support stiffeners are added for a robust material handling design.

Radial Tipped High/Medium Volume Single Width

(RTHS/RTMS)

This efficient design leverages a gradual blade entry angle to coax the air and material into its centrifugal path before accelerating it and launching it out of a radial exit angle.

Material Handling Fan & Blower Arrangements, Accessories, & Design

Material handling fan arrangements commonly used:

Fan arrangements specify how the motors mount to and drive the fans. Heavier material handling fans typically use an Arrangement 9 or Arrangement 1 belt-drive motor to provide more range and control so that if the system gets jammed, it’s less likely to burn out the motor. It also reduces downtime with easier maintenance.

Arrangement 1

Belt drive with an overhung impeller. The fan and motor mount separately to a unitary base.

Arrangement 9

Belt drive with an overhung impeller. The motor mounts to the side of the fan pedestal rather than a unitary base to save space.

In forced draft blower applications where no material is passing through the fan or in systems where the material passing through won’t have an adverse effect on the motor assembly, direct-drive arrangements may also be an option.

Material handling fan accessories & design considerations:

The main concerns for material handling fan applications are keeping the material and air moving and minimizing damage from the abrasive material. Without the right blade style and design, the particles can build up, get clogged, or damage the moving machinery, risking costly downtime and creating a fire hazard. Duct system design and system volume/pressure requirements will help determine the fan/wheel type, horsepower, and materials of construction. The design is based on the specific characteristics of the material. Important questions to ask:

- Is it abrasive?

- Is it tacky/sticky?

- Is there a corrosive element to consider?

- What is the bulk density and volume of the material?

For material handling fan applications, we recommend:

- Venturi Eductors – to transport the materials through low-pressure air with a high-pressure airstream in the pneumatic conveying system

- Sharpened Edges and Breaker Bars – for hard scrap materials

- Inlet Filter or Screen – keeps dust and debris from entering the airstream

- Inlet Silencer – for noise control on the fan inlet or outlet (whichever is the open side)

- Vibration Isolators – when foundational mass is insufficient to support fan operation

- Internal “No-Snag” Finish – (completely smooth welds, etc.) so the material doesn’t get caught up on snag spots

- No-Snag Nose Cone – to cover the wheel hub in the open radial design

- A Fully Open-Wheel – (no outer grid) so nothing can hang on it

- Abrasion-Resistant AR400 Carbon Steel – for heavier-duty material handling applications like metal and aluminum trim

- Teflon – help further reduce material buildup

- Stainless Steel and Specialty Finishes – may be necessary on select fans that require food-grade construction

Talk with Our Material Handing Fan Application Engineers

Our experienced application engineers are ready to help you find the right fan. Whether you’re replacing an existing unit or designing a new system, we’ll make sure you get a solution that fits your specs, timeline, and budget.

Call, email, or submit your info to get started and our team will respond quickly.