High Pressure Blowers & Fans

Engineered for High-Pressure, Low-Airflow Applications

AirPro // Products

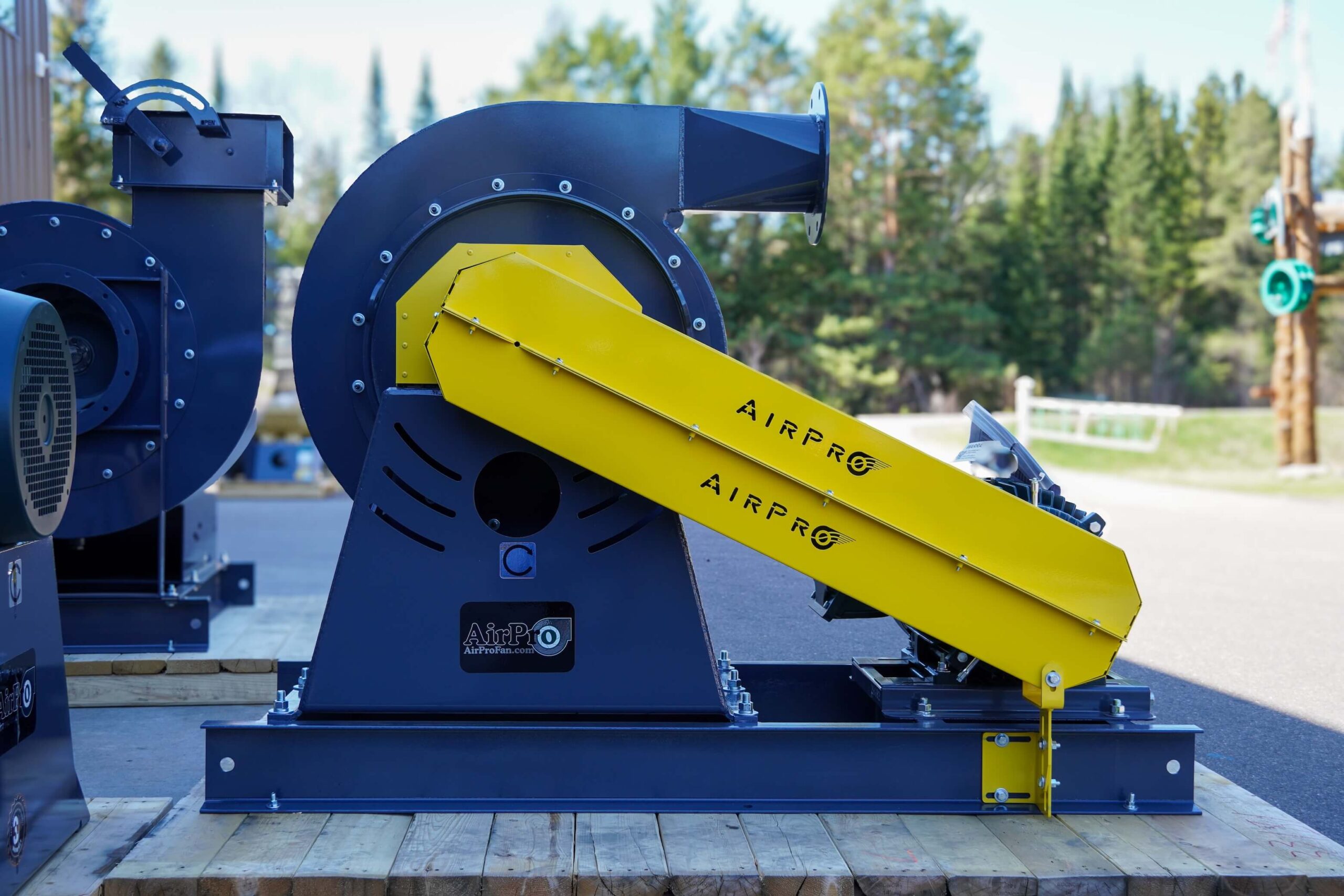

High Pressure Centrifugal Blowers & Fans

High-pressure blowers, which are also referred to as forced draft high-pressure fans, are ideal for continuous-duty industrial applications requiring high static pressure and low airflow. Designed to move clean air, light particulates, or vapors, these fans can also be customized to handle abrasive, sticky, or high-temperature airstreams.

Industrial High Pressure Blower Description

Most high-pressure blower wheels feature straight radial blades set at a 90-degree angle to the hub. This configuration helps minimize debris buildup as clean or particulate-laden air moves through the fan. To meet specific performance needs, some wheels are designed with alternative blade shapes that improve efficiency.

Our line of high-pressure blowers uses a two-number naming convention—an intentional departure from our other product lines. This approach simplifies fan selection by clearly indicating the ANSI standard pipe flange sizes for both the inlet and outlet. By aligning model names with pipe sizes, we make it easier for customers to duct air in and out of the blowers efficiently and with confidence.

Each model’s wheel type is identified by a trailing letter in the product name. We offer both Open and Shrouded wheel options, giving you flexibility to meet a range of performance and application requirements.

Open Wheel Pressure Blowers

P##B

Designed with an open radial steel wheel. Engineered for low air volumes at high static pressures, this product performs well across much of its fan curve due to its open radial design.

P##D

Designed with an open radial steel wheel. Narrower than its B blower counterpart, the D blower hits lower volumes at even higher static pressures. With a continuously rising performance curve, it ideally hits performance points when very low volumes are required.

Shrouded Wheel Pressure Blowers

P##A

Designed with a shrouded, radial, riveted aluminum wheel. Engineered for low air volumes at high static pressures, this product offers another solution for high pressure requirements. Its lower cost of construction due to the riveted wheel and its higher efficiency resulting from the shrouded design concept make it a good offering for a wide range of applications.

P##C

Designed with a shrouded, radial, riveted aluminum wheel. Narrower than its A blower counterpart, the C blower hits lower volumes at even higher static pressures. Similar to the A, its lower cost of construction and higher performing shrouded design yield appealing performance metrics at attractive price points.

P##G

Designed with a shrouded and curved steel wheel. Engineered for peak performance, this product is capable of the highest efficiencies out of the radial designs. This product performs nicely when higher performance is required for an application and clean gas is expected.

High-Pressure Centrifugal Blower Key Features

- Meet unique customer requirements, space limitations, and equipment footprints to achieve API 673/560 requirements.

- Serve the widest range of applications, larger fans, and higher horsepower (1.5 – 1500 HP range) motors, even when fixed speed is required.

- Accommodate consistent wheel width and optimize for low volume with greater efficiency at peak performance.

- Carry our industry-leading 3-Year Gold Standard Warranty (like all AirPro products). Precise, rugged and reliable, we build these fans to last.

Customization Options for High-Pressure Blowers & Fans

- Gas-tight fans

- High-temperature fans

- Special alloys/abrasion & corrosion-resistant materials

- Insulated housing & other thermal controls

- Special coatings & finishes

- Unique sound requirements

- Unique space requirements

- Skidded process system

High Pressure Blower Performance & Design

- Volume: up to 50,000 CFM

- Pressure: up to 130” wg

- Temperature: up to 1500°F

- Static Efficiency: up to 70%

- Drive: Belt and direct

Common High Pressure Blower Applications

Combustion Air:

High-pressure fans move air to combust/burn fuels for different applications, including boilers, furnaces, and ovens.

Selective Catalytic Reduction:

Some of our high-pressure models are used for SCR and often include custom features.

Pneumatic Conveying:

Fans are used to convey anything from cereal to wood chips. Our high-pressure blowers play a role in this process.

Reach // Our Team

Quote

We provide complimentary pricing for all projects.

Schedule

We provide complimentary pricing for all projects.

myAirPro

We provide complimentary pricing for all projects.

Delivery

We provide complimentary pricing for all projects.