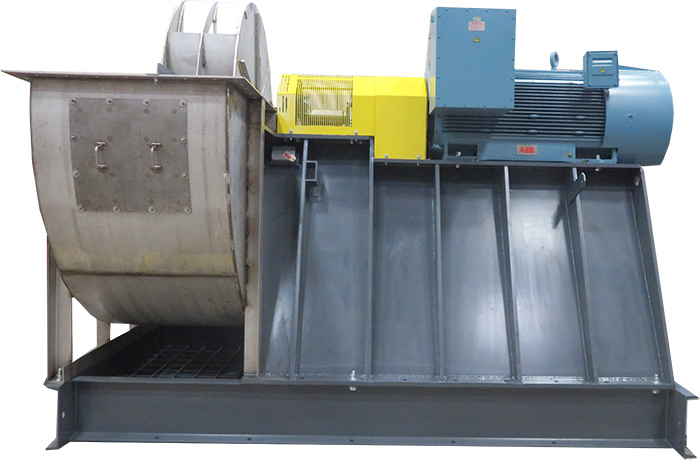

We recently designed and manufactured a custom induced draft fan for a Regenerative Thermal Oxidizer (RTO) application. The design featured our backward-curved technology with an Arrangement 8 configuration.

Extremely robust and very large, the design features a 316L stainless steel airstream with a ferralium wheel, a stuffing box shaft seal, pie split housing, vibration switch, and Resistance Temperature Detector (RTD) sensors for extended bearing life. The fan was mounted on an inertia unitary base with rebar and directly coupled to a 700HP motor. The size of the fan required shipping in parts, with assembly and testing on-site.

The induced draft fan serves as a system booster fan, pulling the dirty air into the RTO. Regenerative Thermal Oxidizers provide odor and pollution control, using extreme temperatures to abate hazardous air pollutants (HAPs) and volatile organic compounds (VOCs). Fans are essential to oxidizer operation, and many custom options were added to this fan to ensure safe and reliable fan operation.

Performance: 114,000 acfm airflow @ 30” w.g. static pressure @ 0.05 lb/ft^3 inlet air density

| Product Type | BCHS (backward curved) |

| Size | 630 (63” diameter wheel) |

| Class | 5 |

| Arrangement | 8 (direct-coupled drive) |

| Horsepower | 700 HP |

| Max Design Temperature | 350°F |

If you have a similar project, contact an application engineer to discuss it in more detail.