Determining the Right Industrial Fan Type

Which industrial fan type do you need in your process to achieve both optimal static efficiency and reliable operation? Considerations include what the fan is processing from clean air to mild particulate to highly abrasive materials, as well as volume and static pressure. Once you know those variables, you can make the fan static efficiency calculation to select the right fan.

Industrial Fan Types, Blade Profiles, and Particulates

The first thing to consider is what will be moving through the blades. Clean air allows both for the most choices and the most efficient fans. If there’s mild particulate in the gas or airstream, potential build-up and balance issues come into play, shifting the optimal fan type and efficiency equation. In heavy material handling applications, there’s only one choice. Let’s get specific.

Optimal High-Efficiency Fan Types for Clean Air

For clean air, all fan types are in the running, but these two offer the benefit of high efficiency given the right circumstances (more on this below):

Fan Types for Light Particulate Loads

For mildly contaminated air, higher-efficiency fans might work. But for extra safety, we recommend radial tipped and industrial exhaust air handling. That’s because in backwardly inclined fans, the air or the gas contacts the fan wheel on the inner part of the blade and gradually releases without much friction. While that’s great for efficiency, it’s bad if you have particulates that can build up and affect fan balance. Using high efficiency fans to move particulate means more maintenance. These are the top fan types for light particulate handling:

These are safer for light material handling and saturated gas applications (like wet scrubbers) because of the blade profile and the way the wheel narrows towards the outer end. Radial tip and industrial exhaust air handling styles are more equipped to shed the material off the end of the blade compared to a constant profile of width.

If unsure of the particulate size, and you want a bit more safety, consider the following fan types:

One Industrial Fan Type for Heavy Material Handling

For heavier material handling of more abrasive material (for example corn husks, manure, paper trim, aluminum chunks, etc.) the only choice is a radial paddlewheel. The radial paddlewheel works because the blades extend right to the hub, so there’s no gap like there is in an industrial exhaust air handling or radial tip. If there were a gap, the inside edge would wear out and destroy the fan wheel pretty fast.

Fan Selection and the Static Efficiency Calculation for Optimal Energy Consumption

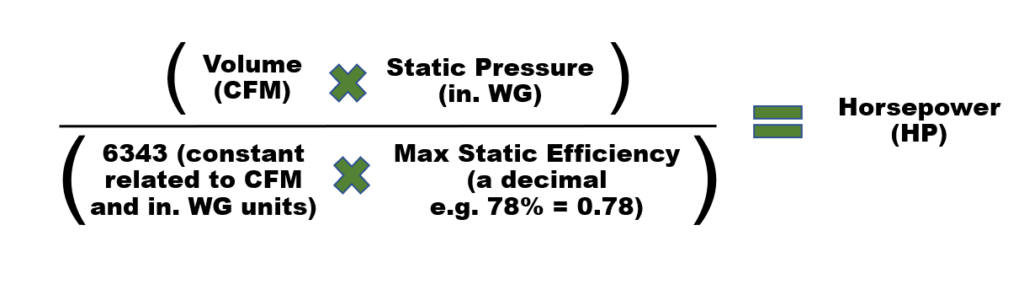

We calculate energy consumption based on the required performance. The basic formula uses a volume to pressure ratio, detailed here:

Fan Static Efficiency Calculation Examples

The more volume you have in comparison with your static pressure, the more likely it is that you can select a high-efficiency fan like backward inclined, backward curved, or maybe an airfoil. Additionally, the calculation can tell you how much horsepower you need to achieve optimal efficiency for the selection.

“Dirty” Process Example

If the process is dirty or unknown, you’re probably using an open paddlewheel. The more abrasion the quicker it will fail, but this fan can move essentially anything. For example, using the above calculation, we’d need a 25-30 HP driver to drive this type of wheel in order to achieve 10,000 CFM of volume at 10 inches WG of static pressure with max static efficiency at roughly 63 percent.

When you know your process involves light particulate, you do have a few other options like the industrial exhaust air handlers and radial designs. Using the same formula, you can determine the horsepower needed and the highest efficiency possible.

“Clean” Applications

With more industrial fan types available for a clean application, static efficiency and energy consumption can help you decide what to use.

For example, let’s say our clean application specifies the same 10,000 CFM of volume at 10 inches WG static pressure we used above. Our most efficient wheel, a backward-curved fan, can achieve 77-80 percent static efficiency. Using the formula, you’ll find that this fan will require about 19.7 horsepower, indicating a 20 horsepower motor, to reach the full performance potential of the volume to static pressure ratio.

Even with a clean application, you may be forced to select a less efficient fan like an industrial exhauster, radial tipped, open or shrouded radial if static pressure is really high and volume is really low. That’s because it requires smaller-width, larger diameter fan wheels with tight space between the blades to get the air through the high pressure with low volume. Let’s say you need to move 100 inches of static pressure, and you only have to move 5000 CFM In this case, your energy consumption would be somewhere in the 67 percent static efficiency range, depending on the fan technology available.

Summary: Industrial Fan Types and Static Efficiency Calculation

How much energy the fan consumes varies greatly by application and which style wheel you have. So review your application, see what you’re moving through the fan, and see if you can increase efficiency from 67 up to 80 percent, for example. If it’s just moving clean air, why not gain that extra efficiency? Your energy consumption is dependent on the style of fans in your system.

Hear it from an Application Engineer

Senior Application Engineer Chet White explains the factors that determine the optimal industrial fan type and the fan static efficiency calculation in this 12-minute whiteboard tutorial.

When you’re ready to start your project or update your maintenance program, reach out, and connect with one of our application engineers to discuss the details of your project.

We welcome comments and questions via our LinkedIn Page, and you can always Contact Us or Request a Quote for more details.