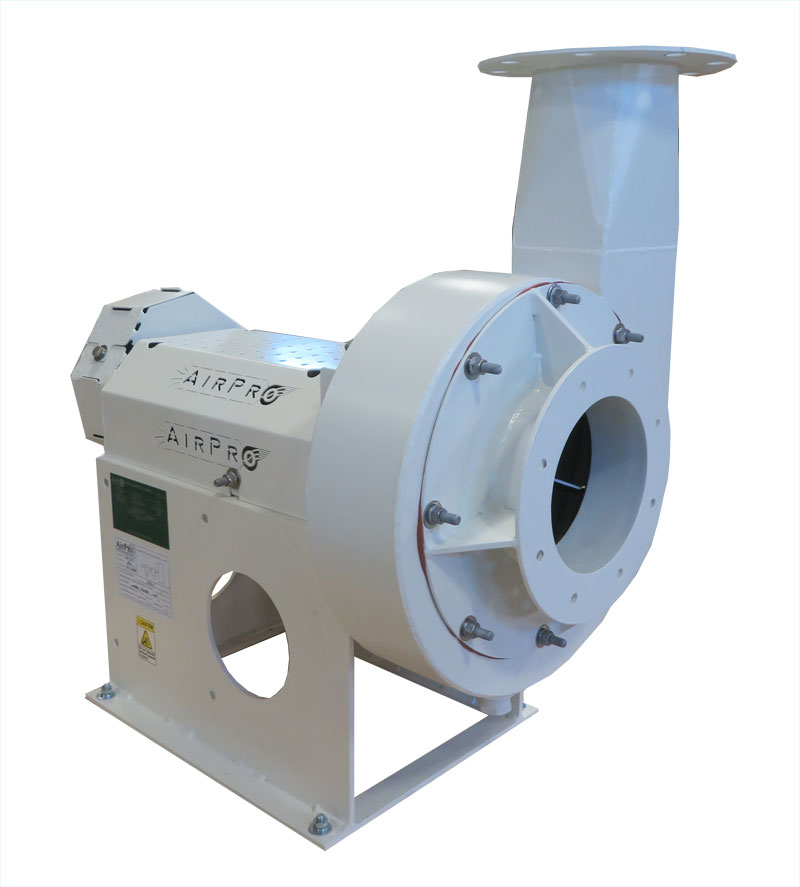

We replaced an industrial exhaust fan originally built by another manufacturer in this brine vapor retrofit installation. The fan is an open radial blade paddlewheel design with a backplate to protect the motor from the material in the air stream. We used AL-6XN® construction material for corrosion resistance and a stuffing box shaft seal to prevent vapor leakage.

Brine vapor processing is a component of many manufacturing processes. In this case, it was a chemical plant for plastics manufacturing. In systems like these that process abrasive materials or corrosive gases, it’s important to customize the fan design with high-density, durable materials. For the exhaust fan in this installation, we chose a stainless steel alloy called AL-6XN®, which has specific characteristics that make it resistant to seawater and other highly corrosive environments for higher efficiency, less downtime for repairs and continued productivity.

Performance: 700 cfm airflow @ 7” wg static pressure @ 0.07 lb/ft^3 inlet air density

| Product Type | IEFB (industrial exhauster) |

| Size | 122 (12.2” diameter wheel) |

| Class | 60 |

| Arrangement | 9 (belt drive) |

| Horsepower | 3 HP |

| Max Design Temperature | 150°F |

If you have a similar project, contact an application engineer to discuss it in more detail. For more information, read about radial fans for material handling.